Mechanical Design and analysis

DTM can develop full turn-key projects taking care for all design (drafting), structural and thermal verification activities or can work on specific design activities thanks to his 3D CAD, FEM and CFD software tools.

Engineering and testing service

DTM offers engineering and testing services including the design of the full experimental (mechanical, electronic, fluidic) and acquisition equipments. Developments are mainly based on National Instruments acquisition systems and Labview for the software. DTM is a qualified laboratory of Emilia Romagna High Technology Network.

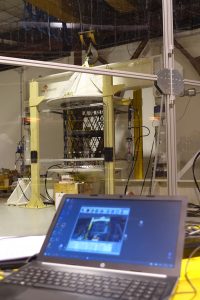

Test facilities for launchers and satellite sub-systems qualification

DTM designs and develops custom test jigs to qualify flight structures like the Tank Support Structure of Sentinel 1 (Thales Alenia Space Rome), Vega Interstage 2/3 and composite outer structures of sub-orbital launchers (Swedish Space Corporation)

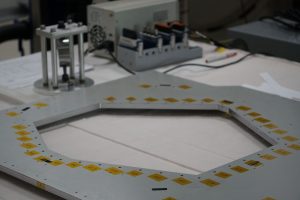

Satellite and launcher structures

DTM is qualified for the realization of composite or metallic sandwich panels like the Exomars sandwich panels developed for Thales Alenia Space Rome and Prisma primary and secondary structures for OHB and instrument structures for Leonardo (ASI Program). For Thales Alenia Space DTM realized the composite thrust structure of the IXV space vehicle.

Space products

DTM designs and develops heat exchangers for ISS and space vehicles like the heat exchangers for the Orion Multi Purpose Crew Vehicle (prime Thales Alenia Space). DTM also develops custom flight components for challenging application like the filling valve developed for Exomars Ultra Clean Zone Analytical Laboratory Drawer.

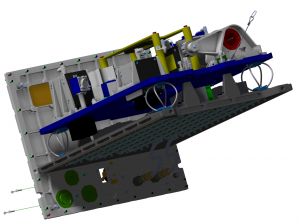

Mechanical Ground Support Equipments

DTM designs and develops mechanical ground support equipments (M-GSE) for instruments and satellites handling, integration, purging and transportation. For Airbus Defence and Space DTM developed the mechanical GSE for the Sentinel 5 instrument: integration stand, trolley, handling adapters, protection covers, purging unit, hoisting devices and transportation container.

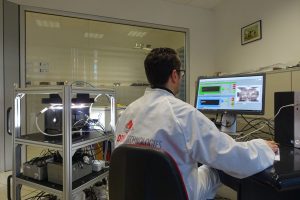

Fluidic Ground Support Equipments

DTM designs and develops fluidic GSE to support flight hardware operations and tests. We are capable to design extra high purity GSE requiring biological, molecular and particle contamination control like the F-GSE built for the Exomars ultra high purity GSE of the Analytical Laboratory drawer developed by Thales Alenia Space Turin.

DTM also designs and develops custom Thermal vacuum chambers like the one built to qualify ISA spring accelerometer for Bepi Colombo mission (Thales Alenia Space Milano) and fluidic GSE for satellite instrument purging.

Composite components design and qualification

DTM has a strong know-how in designing, developing and testing composite structures for space and non space sectors. Also thanks to facilities available in our laboratory like autoclave and NDI equipments, we can design and realize custom products meeting challenging requirements including all the materials and process qualification tests.